Customised ultrasound solutions for you

Solutions for your individual tasks in small and medium-sized businesses and industry

Based on our many years of experience and with our modular ultrasonic components, we will find the most efficient solution for your individual ultrasonic welding tasks.

Phone +49 (0)4193 968 530 and e-mail info@mth-ultraschall.de

Our references for industry solutions

Are you looking for solutions for precise plastic connections?

In this digital booklet, we show you how industry leaders in the automotive, medical technology, packaging, and industrial sectors are already successfully relying on special-purpose machines from mth Ultraschall.

Get special insights into the possibilities of ultrasonic welding!

The company at a glance

- 30 years of experience as a manufacturer of ultrasonic technologies

- Specific expertise in more than 20 industries

- Europe-wide customer relationships

- German research partners and European corporate partners

- Extensive production experience: automotive parts, toy parts, housings of all kinds, medical products, packaging, parts and components for electrical appliances, aerospace, electronics and other industries

International presence through

established business relationships

mth develops and manufactures ultrasonic solutions for individual industrial requirements. Long-standing business relationships ensure that ultrasonic components, hand-held welding equipment, and special-purpose machines are used throughout Europe and internationally.

Examples of specific industry solutions

Your contact person

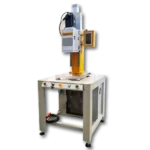

Ultrasonic welding machine with base frame

The ultrasonic welding machine welds all common thermoplastics such as ABS, PA or PP, with a large working area and high positioning accuracy.

Titanium needle sonotrode 40 kHz

The custom-made titanium needle sonotrode is ideal for precise welding of molded parts on bumpers. It ensures high strength and reliable welding results.

Special machine for radiator covers

This special ultrasonic machine was manufactured for welding radiator covers. It offers high precision and reliability for optimum welding results.

Ultrasonic component: This standing ultrasonic generator operates at 40 kHz and 800 W power. It offers protection against short circuit, no-load operation, overload and overtemperature.

Booster/transformer section 1:1 for 20kHz

Ultrasonic component: Titanium ultrasonic booster, for 20 kHz, designed as a transformer piece, for high strength and precision in welding and cutting applications where reliability and performance are crucial.

Converter (transducer)

40 kHz 800 watts USK840

Ultrasonic component converter: The lightweight USK 840 is ideal for use in automated welding and cutting machines, also available with internal cooling connections.

Ultrasonic hand welding gun USH 40E AIR LEMO

The USH 40E hand-held welding gun enables fatigue-free working thanks to its ergonomic 2-component housing, even in awkward positions and at high cycle rates.

40kHz sonotrode, aluminium, for soil samples up to 1.2 mm

This sonotrode is suitable for the 40008004940H ultrasonic hand welding device and for comparable devices with M8 converter threads.

Ultrasonic hand welder USH 800/40 600L

The USH 800/40 600L ultrasonic hand welding device features a handy generator and an ergonomic handle made of colour-anodised aluminium.

Long needle sonotrode,

5 x H=0.87 inches

The needle sonotrode is ideal for the precise welding of moulded parts to a glove compartment panel. It is suitable for reliable use in applications in the automotive industry.

Precisely according to your requirements

Our customised ultrasonic solutions are suitable even for complex production processes. As a partner to SMEs and industry, we offer you a range of ultrasonic components, system solutions and comprehensive engineering expertise for a wide range of applications.

We offer a product portfolio with the highest standards of quality and function – Made in Germany:

- First-class welding results

- Professional integration into your application

- Longevity of all ultrasonic components and modules

- Economical overall solution

Ask us your questions

- Do you need a replacement for a sonotrode or another ultrasonic component?

- Are you looking for a new solution for the production of your components?

- Do you want to produce cheaper, faster, better or with higher quality?

- Or do you have another problem that you would like to solve?

Replacement and repair service

We offer the right solution

The tasks are as varied as the clients and industries we work for. We work closely with you to find the right solution – from individual components to complete systems.

Simply enquire now: Phone +49 (0)4193 968 530 and via e-mail info@mth-ultraschall.de

Thermoplastics, weldable plastics

Get an overview of the most important plastics that can be welded – thermoplastics. Our PDF file for download not only contains a list of these plastics, but also provides technical information on their properties and special features when welding.

Source: https://rittmeyer-beri.de/ultraschall-buch/funktionsprinzip

References special-purpose machine engineering

mth supplies the right special-purpose machine for large quantities and complex component geometries. The spectrum ranges from manual workstations in modular design to rotary indexing table systems with up to 100 individual welding points.

Source: https://rittmeyer-beri.de/ultraschall-buch/funktionsprinzip

Source: https://rittmeyer-beri.de/ultraschall-buch/funktionsprinzip

Reproducible and high-quality welding results guaranteed

We design our components and customised solutions with the help of our modular ultrasonic product range. The intelligent control software is an integral part of this range. We create the best conditions for easy integration into our customers’ machine environment. Our product portfolio is characterised by the following features:- Functional design

- Advanced technology

- Robust ultrasonic tools

- Sophisticated control software

We are ready for the digitalised production of the future!

Do you have questions?

We are happy to help you personally with your individual wishes and requirements: