Ultrasonic welding machines

Ultrasonic welding is one of the most energy-efficient technologies for joining thermoplastics. In contrast to purely thermal processes, microscopic movements of the sonotrode in the kHz range mechanically excite the joining zone during ultrasonic welding, resulting in localised heating. The concentrated energy supply with outputs of up to 2,000 W melts the joining zone within fractions of a second. Sensitive peripheral areas do not heat up, the energy finds its way in a targeted manner. Almost as quickly as the plastic was liquefied, the melt solidifies again after the ultrasound is switched off. As a result, the welded components are immediately mechanically resilient.

Quality of our ultrasonic welding machines

We develop, design and produce all of our devices and machines in Germany at our Henstedt-Ulzburg site in the immediate vicinity of Hamburg. Every welding machine is subject to strict quality and functional testing. With these starting conditions, the flexibility of a medium-sized company and decades of experience, we offer our customers ultrasonic welding machines for efficient industrial production.

-

Ultrasonic welding machine TSM 20, bench-top version

To product » -

Ultrasonic welding machine TSM 20, freely configurable extensions

excl. VAT

add. shipping fees

To product » This product has multiple variants. The options may be chosen on the product page -

Ultrasonic welding machine with base frame TSM 20 performance

To product » -

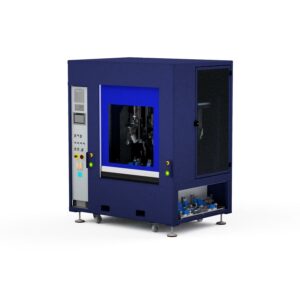

Compact plastic welding machine with ultrasound

999.999,00 €excl. VAT

add. shipping fees

To product » This product has multiple variants. The options may be chosen on the product page -

Universal plastic welding machine with ultrasound

999.999,00 €excl. VAT

add. shipping fees

To product » This product has multiple variants. The options may be chosen on the product page -

Flexible plastic welding machine with ultrasound

999.999,00 €excl. VAT

add. shipping fees

To product » This product has multiple variants. The options may be chosen on the product page

Ultrasonic bench welding machines

With the TSM 20 bench welding machine, mth supplies a machine for joining components with a single joining zone. This process is used wherever large quantities need to be processed efficiently. For partially or fully automated production lines, mth supplies feed units and control systems that transfer the basic idea of the table welding machine to higher-level production cells. Areas of application for bench welding machines include toy parts, electrical housings, medical products such as infusion tubes and much more.

Customised ultrasonic welding machines

Complex plastic parts with many welding points can be produced in large quantities if several welds are carried out simultaneously. Vehicle interior panelling and add-on parts in particular often consist of a large number of components that need to be joined with high repeat accuracy and process reliability. But also in the area of household appliances, for example, there are control panels, built-in parts or drive components that are assembled and welded together from different parts.

mth delivers the perfect solution for every application! Our customized machines are as unique as the products for which they were designed. We are happy to advise you right from the design stage of your components in order to recognise potential welding challenges at an early stage and identify possible solutions.

Our product range of ultrasonic components

Do you have any questions or would you like a customised offer?