Structure of an ultrasonic welding machine

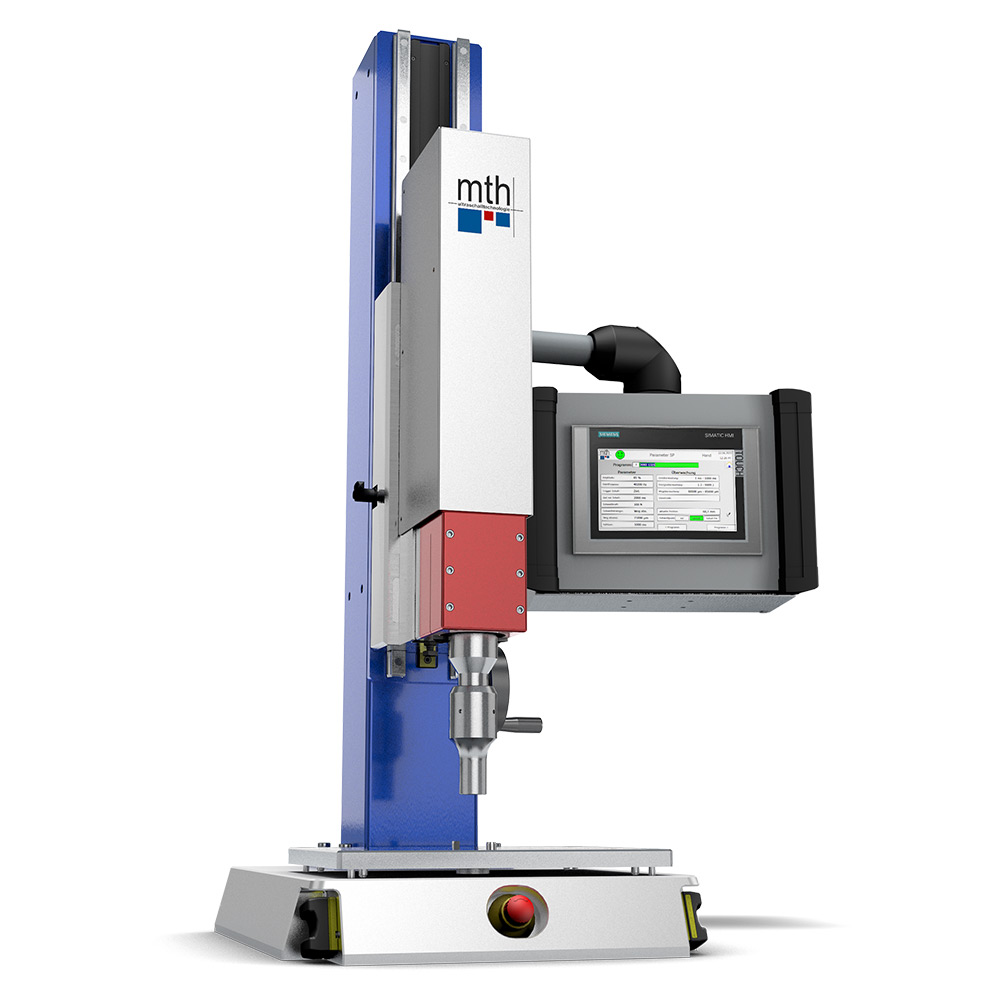

An ultrasonic welding machine consists of a large number of coordinated components. The most important ones include The ultrasonic generator, the welding unit, consisting of the ultrasonic converter, ultrasonic booster and sonotrode, the holding and feed mechanism for moving the welding unit and a programmable logic controller (PLC), which regulates and monitors the entire welding process.

The ultrasonic generator supplies the high-frequency voltage of several hundred volts and an operating frequency of between 15,000 and 70,000 Hz. It can generate an output of up to several kilowatts. The generator has a microprocessor control system that continuously adjusts the frequency of the electrical oscillating circuit to the resonant frequency of the oscillating pattern. It also keeps the amplitude constant over a wide power range.

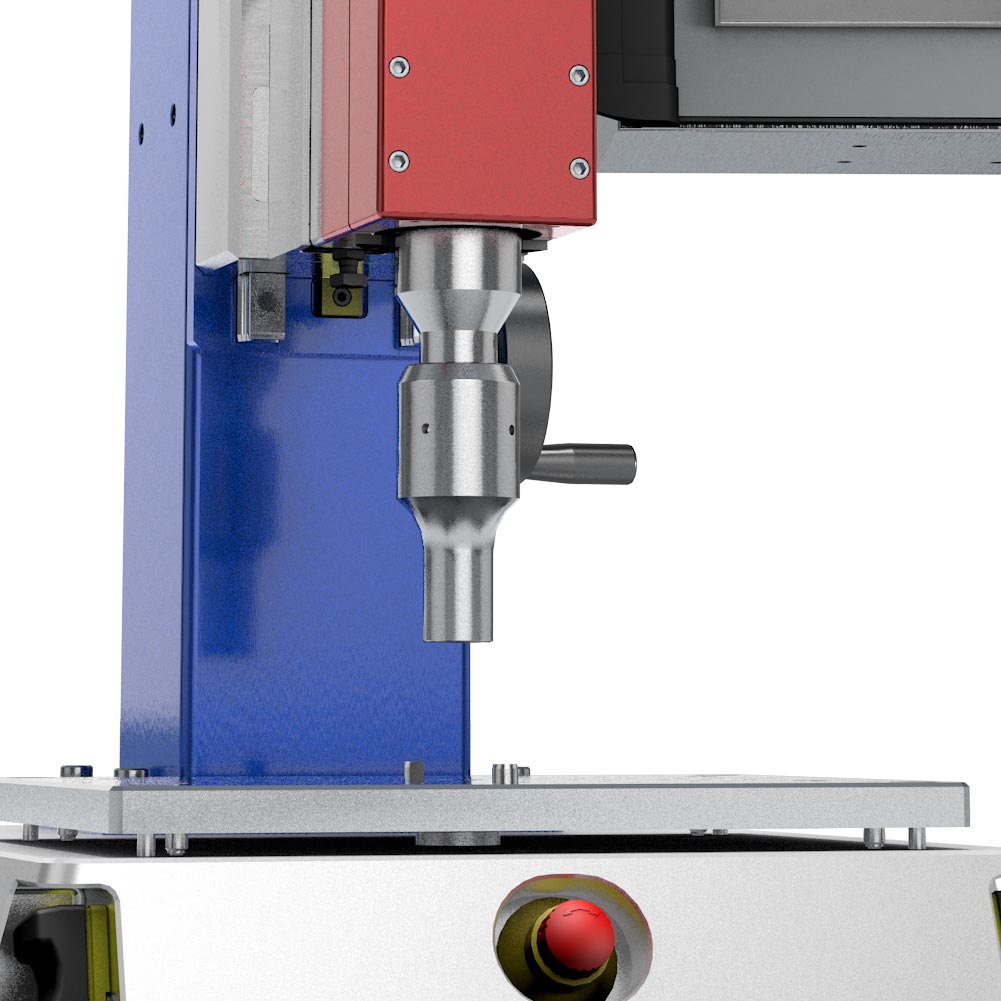

In the ultrasonic converter, so-called piezoelectric ceramic disks (PZT ceramics) convert the supplied electrical energy into a mechanical deflection (oscillation) with a defined amplitude (amplitude) and frequency.

Depending on the operating frequency, the converter provides a mechanical amplitude of approx. 5 – 10 µm. This is often not sufficient to achieve the desired welding or cutting effect on the active sonotrode surface. With the ultrasonic booster (amplitude transformation piece), the amplitude at the transition to the sonotrode can be increased up to four times.

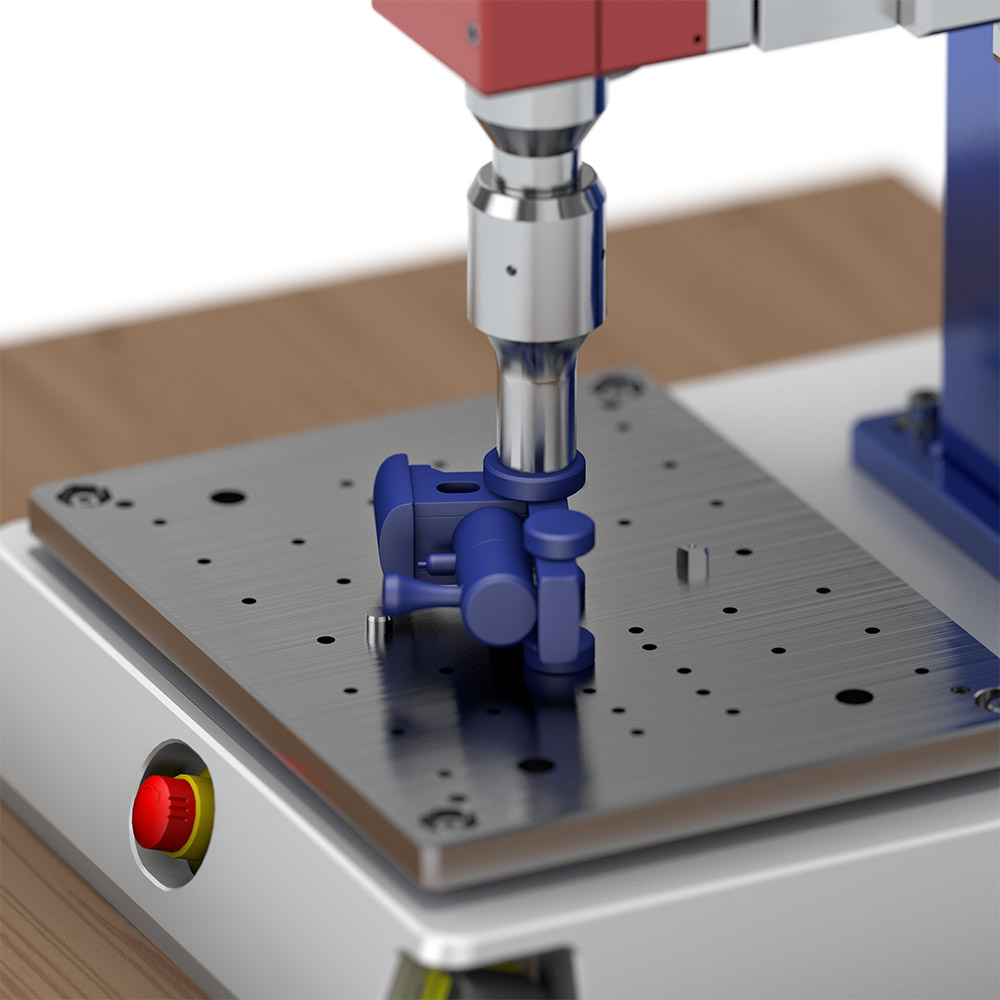

The sonotrode is the tool that ultimately transmits the ultrasonic vibrations to the workpiece. The geometry of the sonotrode can be used to further increase the amplitude (transmission ratio of the sonotrode). The limits are essentially determined by the material properties.

The assembly of the three components converter, booster and sonotrode is referred to as the oscillating structure or welding unit .. The pneumatic or servo-electric feed mechanism moves the welding unit towards the workpiece and supplies the required welding pressure.

The control unit is one of the central components of the ultrasonic welding machine. It controls the generator, converter, welding unit and all other functional elements so that the conditions for the entire welding process are maintained.

Source: https://rittmeyer-beri.de/ultraschall-buch/funktionsprinzip

Continue to our ultrasonic products

* * * * *Overview page of all ultrasonic products

On the following page you will find an overview of all our product groups – from accessories to the manual welding machine to the custom-made ultrasonic welding machine. To the product overview » * * * * *Product group Ultrasonic manual welding machines

Hand-held welding machines, hand-held welding guns, hand-held welding devices and accessories for a wide range of commercial and industrial applications. To the manual welding machines » * * * * *Ultrasonic welding machines product group

We develop, design and produce in Germany in the immediate vicinity of Hamburg. Each welding machine is subject to strict quality and functional testing and is designed for efficient industrial production. To the ultrasonic welding machines »Do you have questions?

We are happy to help you personally: