Friction welding machines

Thermoplastics can be joined together efficiently using vibration welding or rotary welding (also known as rotary friction welding, sometimes referred to as friction welding). Compared to ultrasonic welding, the amplitudes are 1-2 orders of magnitude higher and the frequencies are lower on the same scale. Vibration welding is always used where components are asymmetrical or cannot be joined rotationally due to interfering contours. Rotary welding is a cost-effective variant of friction welding. Components can also be welded together at the correct angle using an appropriate control system.

Sirius Electric – exclusively represented by mth!

Since 15 December 2021, mth from Henstedt-Ulzburg has been the exclusive Sirius Electric product representative for Germany and Denmark. With its many years of experience in the field of friction welding, Sirius Electric is the ideal addition to the mth product portfolio, so that all plastic welding processes can now be offered from a single source.

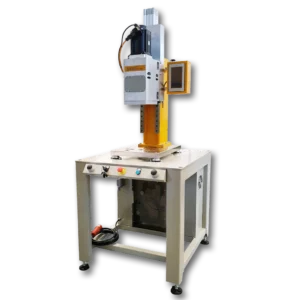

VSP409 vibration welding machine

The VSP409 vibration welding machine is used for welding thermoplastics with complex contours when welding with conventional methods such as ultrasound or hot plate is not possible. The vibration movement is circular and – unlike

conventional vibration welding machines, the vibration movement is circular and is achieved by a targeted imbalance on the drive unit. The machine can be loaded manually or integrated into a production line. As an individual workstation, the machine can optionally be supplied with a base frame or a closed cabin.

Customized vibration welding machines

Complex plastic parts with interfering contours can be produced in large quantities with short cycle times. The fields of application range from simple plastic housings and vehicle parts to spectacles and fashion accessories.

mth delivers the perfect solution for every application! Our customized machines are as unique as the products for which they were designed. We are happy to advise you right from the design stage of your components in order to recognise potential welding challenges at an early stage and identify possible solutions.

Do you have any questions or would you like an individual offer?

We are happy to help you personally: