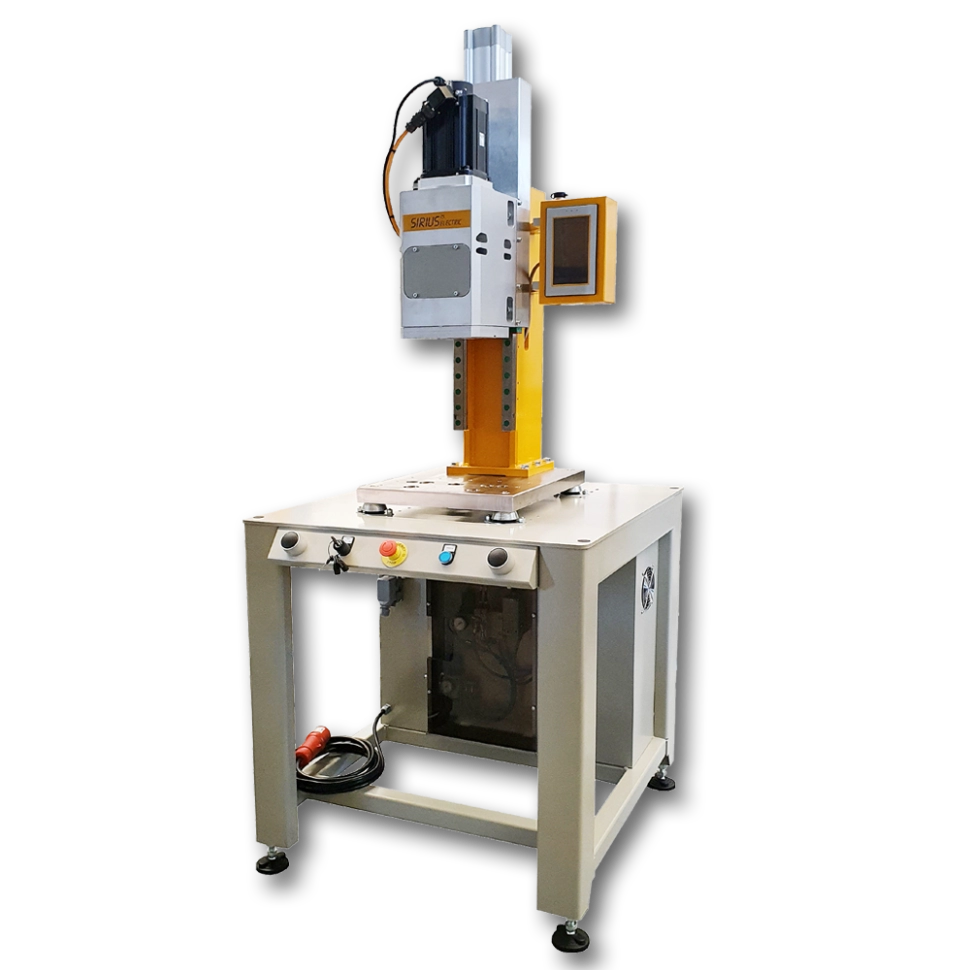

Vibration welding machine with base frame Sirius Electric VSP409

39.800,00 €

excl. 19% VAT add. shipping fees

With pneumatic feed

Out of stock

Vibration welding machine with base frame Sirius Electric VSP409

The VSP409 vibration welding machine is used for welding thermoplastics with complex contours when welding with conventional methods such as

e.g. ultrasound or heating plate is not possible. The vibration movement is circular and – unlike with conventional vibration welding machines – is generated by a specific imbalance on

the drive unit. This results in a defined geometry of the welding movement.

Technical data

| Vibration amplitude: | 0.2 – 2 mm |

| Frequency: | 0 – 200 Hz |

| Power: | 3,3 kW |

| Unit weight: | max 6 kg |

| Stroke: | 160 mm |

| Clamping surface: | 200 mm x 200 mm |

| Welding force: | max. 2.500 N |

The entire machine frame of the VSP409 vibration welding machine, both the base and the column, are made of torsion-resistant welded steel profiles. A brushless DC motor with state-of-the-art speed control is used as the drive motor. The stroke motion takes place via a pneumatic traversing unit with finely adjustable

proportional movements that run in precisely ground prismatic guides. A centralised lubrication system ensures permanent lubrication and a long service life for the slideways. The entire

welding process is controlled and monitored by a modern microprocessor control system. A user-friendly touch display is already included as standard.

It can be set to a fixed time as well as to the welding path. The travel distance is recorded using a high-resolution distance measuring system. Individual joining pressures can be programmed for the individual lowering, welding and cooling phases. The control unit enables the creation of a total of 20 individual welding programmes.

Basic functions of the VSP409 vibration welding machine

The VSP409 vibration welding machine is equipped with a modern touch panel microcontroller that enables intuitive operation. The following functions are included as standard:

– Memory for 10 welding programmes

– Welding on time, absolute path and incremental path

– Typical time resolution 10 ms

– freely programmable enamel thickness

– freely programmable vibration frequency

– Displacement transducer with a resolution of 10 μm

– Welding and cooling pressure adjustment via electronic

Proportional valves

– Limit value monitoring with adjustable min. and max. limits

– quantity counter for good and bad parts

– Bad part signal acoustic and with potential-free relay output

– USB interface for welding data acquisition

– Operator languages: German, Italian, English, French

Vibration welding machine – Areas of application

Vibration welding as a variant of friction welding is used where interfering contours do not permit rotary friction welding.

- Vehicle technology: In vehicle construction, electrical fuse and distribution boxes, crankcase ventilation etc. are joined using vibration welding.

- Drive technology: Conveyor elements on synchronous belts can be efficiently attached to the carrier belt using linear vibration welding.

- Optical industry: For high-quality spectacle frames, vibration friction welding replaces the tedious process of gluing acetate plates with acetone.

Downloads

Leaflet VSP409 vibration welding machine