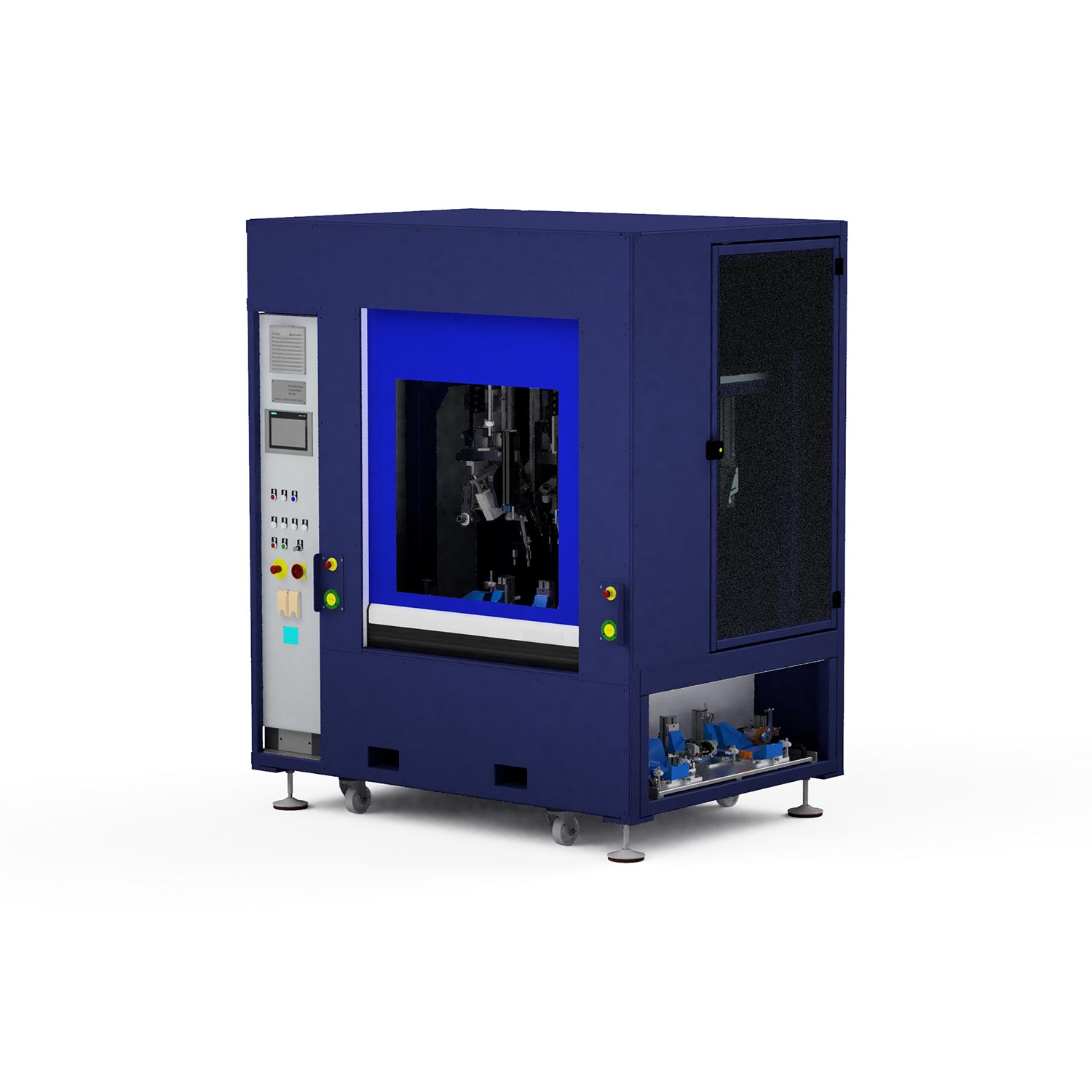

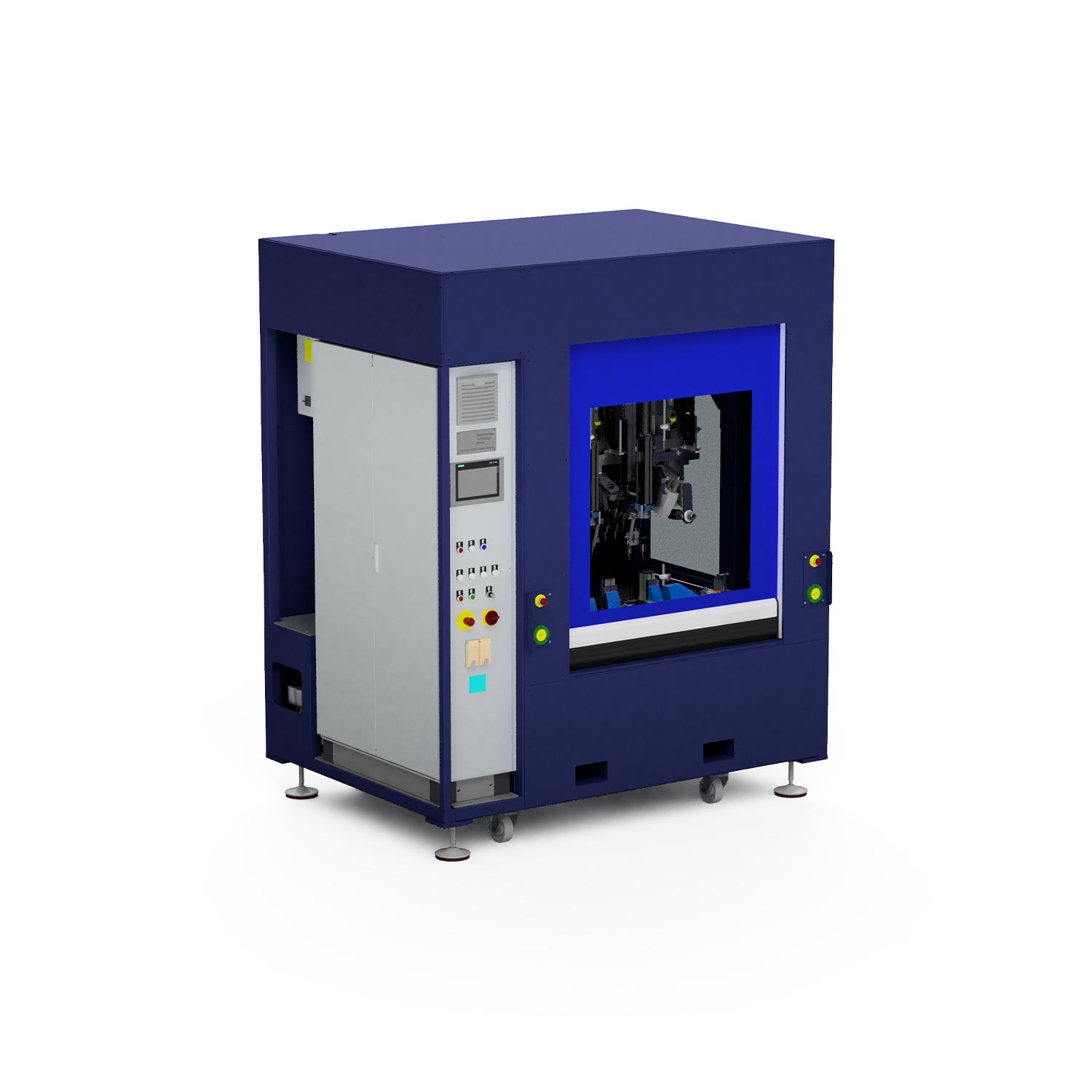

Universal plastic welding machine with ultrasound

999.999,00 €

excl. VAT add. shipping fees

We are currently revising the prices for this product. If you are interested, we look forward to receiving your enquiry.

Universal plastic welding machine with ultrasound for customised mass products

The Standard. Our tried and tested universal plastic welding machine with ultrasound for stand-alone operation.

This universal ultrasonic plastic welding machine is ergonomically optimised for one-man operation. A generously dimensioned high-speed door with safety function allows parts to be changed quickly. The scope of delivery usually includes 2 article holders, of which the one not required is stored in the side of the machine to save space. All upper tools remain firmly set up and are approached with high accuracy via the precise servo-electric machine table. Depending on the configuration, up to 2 components per article holder can be welded on 2 table positions. All operating elements and the control cabinet are accessible from the front or side, so that the machine can be installed directly against the building wall to save space thanks to its low installation depth of just 1,500 mm.

The ultrasonic devices are based on our proven 40 kHz converters from the USK840 series. All sonotrodes are designed by mth based on the CAD component contour and manufactured from high-quality titanium. The item holder, which is also manufactured according to CAD data, is made of our special plastic, which has been tried and tested for decades and offers maximum protection against surface damage, even with sensitive or painted components.

The machine shown is configured for the assembly of the acoustic fleece of two D-pillar panellings (left/right) with a total of 6 welding points in 2 positions, article monitoring by means of DataMatrix scanning and individual part scanning at 3 positions.

Technical data

| Generators: | Up to 8 ultrasonic generators with 40 kHz / 800 W |

| converter: | Up to 16 converters |

| Dimensions: | Basic machine: WxDxH: 2,100 x 1,500 x 2,560 mm |

Basic equipment of the universal plastic welding machine with ultrasound

- Robust high-speed door with monitoring

- Ergonomic start button without switching travel

- incl. Siemens S7-1500 control system Comfort Panel

- System pneumatics from Festo / Aventics

- Illuminated workspace

- incl. Welding on path, time and energy Extensive monitoring functions

Optional equipment

- QR code or data matrix scanner with release interface to higher-level MES

- User identification with SmartCard

- Parts and components queries

- Digital individual pressure control via electronic proportional valves

- Position measuring system on each traversing unit

Optional functions

- Data exchange with higher-level control technology

- User-defined behaviour for nIO parts

Additional information

| QR-Code- oder Datamatrix-Scanner | with QR code or data matrix scanner, without QR code or data matrix scanner |

|---|---|

| Benutzeridentifikation SmartCard | with user identification via SmartCard, Without user identification via SmartCard |

| Bauteil- und Komponentenabfrage | with part and component query, without part and component query |

| Digitale Einzeldruckregelung | with digital individual pressure control, without digital individual pressure control |

| Wegmessystem | with distance measuring system, without distance measuring system |