High-level special-purpose machine engineering

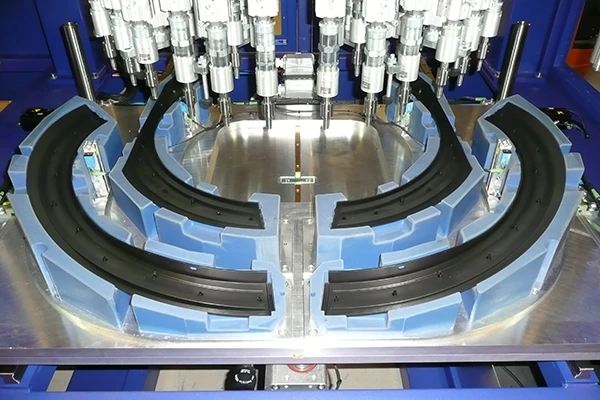

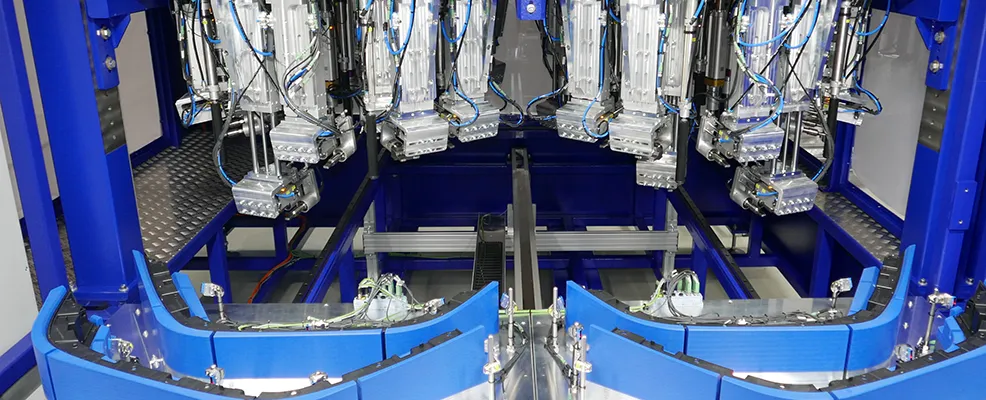

Customised special-purpose machines for plastic joints: mth Ultraschalltechnologie is your specialist for the development and manufacture of special-purpose machines for optimising and automating your production of plastic joints.

We work with medium-sized companies and industrial enterprises throughout Europe. Through the targeted use of individual automation solutions, we help our customers save time and money. From the initial idea to the final implementation, we deliver special-purpose machines of the highest standard.

Cross-industry application

Our special-purpose machines are used in numerous industries where the manufacture of plastic compounds plays a central role. Whether in the automotive industry, medical technology or the packaging sector, our technologies offer precise and efficient solutions.

Precision and versatility in manufacturing: We develop special-purpose machines for specific requirements, including:

- Precise tool removal

- Thermal deburring

- Label inspection

-

Compact plastic welding machine with ultrasound

999.999,00 €excl. VAT

add. shipping fees

To product » This product has multiple variants. The options may be chosen on the product page -

Flexible plastic welding machine with ultrasound

999.999,00 €excl. VAT

add. shipping fees

To product » This product has multiple variants. The options may be chosen on the product page

Our references for industry solutions

Are you looking for solutions for precise plastic connections?

In this brochure, we show you how industry leaders in the automotive, medical technology, packaging, and industrial sectors are already successfully relying on special-purpose machines from mth Ultraschall.

Get special insights into the possibilities of ultrasonic welding!

Thermoplastics, weldable plastics

Get an overview of the most important weldable plastics – thermoplastics. Our PDF file for download not only contains a list of thermoplastic materials, but also provides information on their properties and special features when welding.

Source: https://rittmeyer-beri.de/ultraschall-buch/funktionsprinzip

High precision, seamless integration in confined spaces

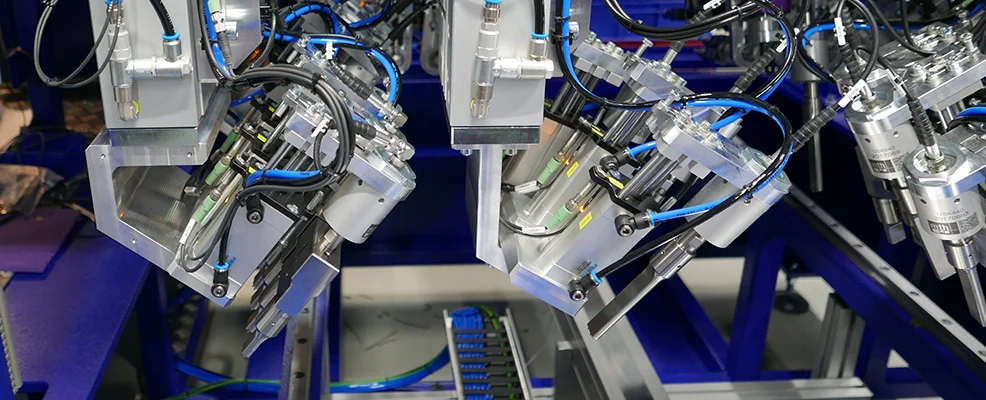

Our solutions are characterised by high precision and seamless integration into existing production processes.

Our focus is on customised automation solutions that ensure efficiency, safety and smooth integration into your production environment. This enables us to sustainably increase the performance of your manufacturing operations.

A particular focus of our work is the development of space-saving special-purpose machines that take up only a few square metres. Even in confined spaces, we can implement efficient automation solutions that significantly improve your production processes.

Methodical engineering and special machine construction

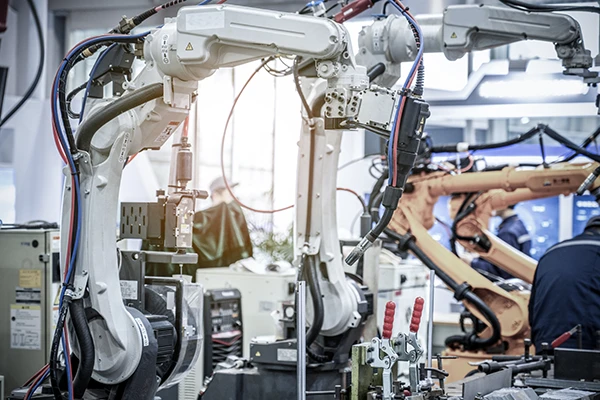

The days when special machine construction was primarily a question of mechanics are long gone. Control systems, electrical engineering, safety technology and various software-based tasks now play an equally important role in the engineering challenges we face in our company, both in design and manufacturing.

In addition, adjacent departments of our clients impose additional requirements. Our approach to methodical engineering therefore plays a decisive role in meeting all requirements.

Versatility in joining technology

The joining technology section emphasises the versatility of our customised machines, which are capable of various processes such as hot caulking, electrofusion welding, high-frequency welding, laser transmission welding, circular welding and friction welding.

Customised machine engineering for your needs and complex challenges

Custom-built machine engineering – Made in Germany

Well-designed production systems are the result of in-depth expertise. We develop machines and system components for our customers entirely in-house, taking into account the entire production process and thus sustainably reducing production costs across the entire value chain.

Well-known customers from various industries throughout Europe are already benefiting from our expertise and automation know-how, which has grown over 30 years. We will show you the adaptability of our customised machines, which master methods such as hot bonding, electrofusion welding, high-frequency welding, laser transmission welding, orbital friction welding and friction welding. Tailored to your specifications, these machines guarantee seamless assembly and robust connections suitable for various materials.

Reliability and quality

Interested in finding out more details?

Further information on special-purpose machine engineering

* * * * *

Industry solutions

Diverse solutions for various industries: We manufacture a wide range of ultrasonic components, ultrasonic systems and turnkey special-purpose machines that meet the requirements of various industries in Europe.

Continue to industry solutions »

* * * * *

International presence through

established business relationships

mth develops and manufactures ultrasonic solutions for individual industrial requirements. Long-standing business relationships ensure that ultrasonic components, hand-held welding equipment, and special-purpose machines are used throughout Europe and internationally.

Do you have questions?

We are happy to help you personally:

Do you have questions?

We are happy to help you personally with your individual wishes and requirements:

Customised switch cabinets

Perfectly customised to your special-purpose machine: We build a switch cabinet built to your needs.