Ultrasonic welding machines

-

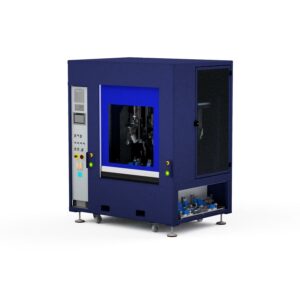

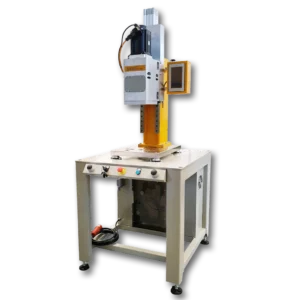

Universal plastic welding machine with ultrasound

999.999,00 €excl. VAT

add. shipping fees

To product » This product has multiple variants. The options may be chosen on the product page -

Ultrasonic welding machine TSM 20, freely configurable extensions

To product » This product has multiple variants. The options may be chosen on the product page -

Compact plastic welding machine with ultrasound

999.999,00 €excl. VAT

add. shipping fees

To product » This product has multiple variants. The options may be chosen on the product page -

Flexible plastic welding machine with ultrasound

999.999,00 €excl. VAT

add. shipping fees

To product » This product has multiple variants. The options may be chosen on the product page

Our references for industry solutions

Are you looking for solutions for precise plastic connections?

In this brochure, we show you how industry leaders in the automotive, medical technology, packaging, and industrial sectors are already successfully relying on special-purpose machines from mth Ultraschall.

Get special insights into the possibilities of ultrasonic welding!

Ultrasonic components, machines, and devices

Converter

40 kHz 800 watts USK840

The lightweight USK 840 is ideal for use in automated welding and cutting machines.

* * *

USH 40E AIR LEMO hand-held welding gun

This hand-held welding gun

with ergonomic 2-component housing for fatigue-free working

* * *

Aluminum sonotrode with M8 thread

This sonotrode is

suitable for all handheld welding devices with M8 converter thread.

* * *

USH 800/40 600L hand welding machine

The USH 800/40 600L features a handy generator and an ergonomic handle made of colored anodized aluminum.

* * * *

Long needle sonotrode,

5 x H=0.87 inches

The needle sonotrodeis ideal for the precise welding of molded parts to a

glove compartment panel.

* * *

Ultrasonic welding machine with base frame

This ultrasonic machine welds all common thermoplastics with positioning accuracy.

* * *

Ultrasonic component: Sonotrode

The custom-made titanium needle sonotrode is ideal for precise welding of molded parts on bumpers.

* * *

Special machine for radiator covers

This special machine

was manufactured for welding

radiator covers.

* * *

This upright

ultrasonic generator

operates at 40 kHz and

800 W power.

* * *

Ultrasonic component: Booster

Titanium booster, 20 kHz, as transformer unit, for high strength and precision in welding and cutting applications

* * *

Your solution for customised industry solutions!

We are your expert for customized solutions in ultrasonic technology and automation! Discover how we fulfil the unique requirements of different industries and write success stories together with our customers. Find out more about our commitment to innovation, quality and customer satisfaction.

Rotary and vibration welding machines

We are here for you

Our many years of expertise enable us to develop customised ultrasonic components that are precisely tailored to your requirements. From concept to implementation, we are your reliable partner.

Our dedicated team of experts, whose expertise covers automation, electrical engineering, assembly and machining, is on hand to advise you.

We have a solution for every requirement – or we can tailor one for you.

Current and key topics on our site

- We manufacture sonotrodes according to your requirements and needs.

- Erfahren Sie mehr über umfassendes Angebot an Ultraschall-Komponenten

- Perfect for manual welding – mth ultrasonic hand-held welding devices

- Customised special-purpose machines for the manufacture of plastic compounds

- We are partners with Sirius Electric

References special-purpose machine engineering

mth supplies the right special-purpose machine for large quantities and complex component geometries. The spectrum ranges from manual workstations in modular design to rotary indexing table systems with up to 100 individual welding points.

Source: https://rittmeyer-beri.de/ultraschall-buch/funktionsprinzip

Thermoplastics, weldable plastics

Get an overview of the most important weldable plastics – thermoplastics. Our PDF file for download not only contains a list of thermoplastic materials, but also provides information on their properties and special features when welding.

Source: https://rittmeyer-beri.de/ultraschall-buch/funktionsprinzip

Do you have any questions and would like advice?

We are happy to assist you personally with your individual wishes and requirements for ultrasonic systems:

from sonotrodes and ultrasonic welding machines to special-purpose machines.

Ultrasonic products and accessories

-

Ultrasonic hand welder USH 400/40 40E

3.690,00 €excl. 19% VAT

add. shipping fees

To product » -

Ultrasonic manure belt welder USH 800/40 40E compact

3.290,00 €excl. 19% VAT

add. shipping fees

To product » -

Converter (transducer) 30 kHz 1500 Watt

1.295,00 €excl. 19% VAT

add. shipping fees

To product » -

Transport case for hand welder

125,00 €excl. 19% VAT

add. shipping fees

Delivery time: approx. 2-3 working days

To product »

Special-purpose machine engineering

Customised special-purpose machines designed for tasks such as precise tool removal, thermal deburring and label inspection are at the heart of our commitment.

We place great emphasis on customisation to ensure efficiency, safety and seamless integration. This enables the improvement of your production processes in line with your specific requirements.

The design of space-saving special-purpose machines is a particular focus for us. This enables us to efficiently optimise your automation even in the most confined spaces.

Special-purpose machine engineering

Customised special-purpose machines designed for tasks such as precise tool removal, thermal deburring and label inspection are at the heart of our commitment.

We place great emphasis on customisation to ensure efficiency, safety and seamless integration. This enables the improvement of your production processes in line with your specific requirements.

The design of space-saving special-purpose machines is a particular focus for us. This enables us to efficiently optimise your automation even in the most confined spaces.

mth special-purpose machines engineering

Customised special-purpose machines designed for tasks such as precise tool removal, thermal deburring and label inspection are at the heart of our commitment. We place great emphasis on customisation to ensure efficiency, safety and seamless integration. This enables you to improve your production processes in line with your specific requirements.

Increase the effectiveness of your processes by using customised special-purpose machines for individual production in the fields of joining technology and plastics processing.

mth Ultraschalltechnologie

Our ultrasonic technology has been setting new standards in plastic joining technology for over 30 years.

Request a special design

Are you interested in an ultrasonic welding machine developed to meet your specific requirements? We look forward to receiving your inquiry and talking to you.

Experience our individual concepts of ultrasonic welding machines!

Example: Welding an airbag cap

Watch this video to see how an airbag cap is welded and tested fully automatically.

Various welding processes are used in this rotary indexing table system — hot gas welding (hot air welding) and ultrasonic welding. Weld rivet monitoring using a camera system is standard, as is fully automatic article removal with handling.

International presence through

established business relationships

mth develops and manufactures ultrasonic solutions for individual industrial requirements. Long-standing business relationships ensure that ultrasonic components, hand-held welding equipment, and special-purpose machines are used throughout Europe and internationally.